Standardization

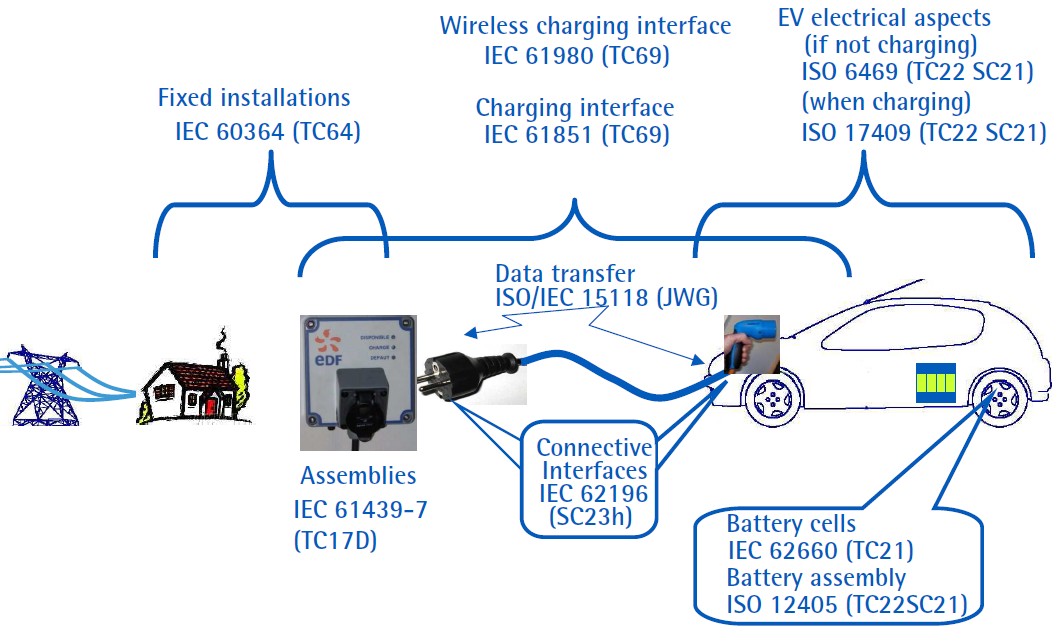

Nowadays, electric mobility becomes a trending issue and penetrate the market rapidly. However, standardization is essential in order to ensure the safety and compatibility of various components of EVs such as the lithium-ion batteries and battery traction systems. Below figure gives an overview of variant developed standards from grids to EV’s.

Figure 1. developed standards from grids to EVs

The battery system as a large and very costly component of an electric vehicle has a tremendous impact in safety and reliability of EVs. So that, many standardization institutes have shown great concern regarding various aspects of lithium batteries. At worldwide level, standardization is mainly under the competence of two institutions: The International Electrotechnical Commission (IEC), founded on 1906, and the International Organization for Standardization (ISO), founded on 1946. Compare to IEC, which is work on electric components and electric supply infrastructure, ISO considers an electric vehicle, as a whole. The lithium-ion batteries standards are developed from three main perspectives of design, safety and performance.

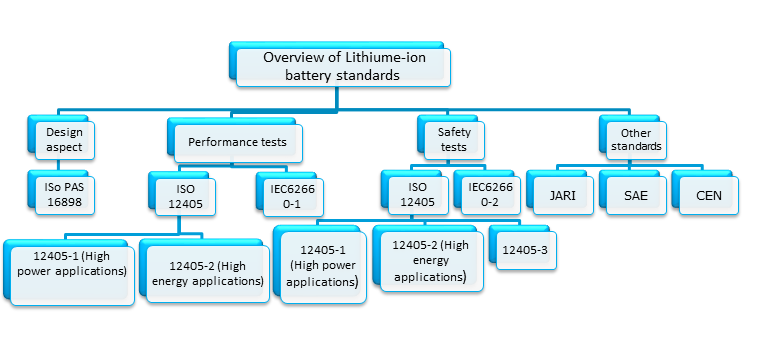

The main standards, developed for Lithium-ion batteries by ISO/IEC, are summarized as below:

• Electrically propelled road vehicles: ISO/NP PAS 16898

• Lithium batteries- battery pack and system level: ISO 12405-1, 12405-2, 12405-3

• Secondary lithium cells: IEC 62660-1, IEC 62660-2

There are also some other standards relating to EVs batteries like JARI, SAE and CEN

Figure 2 illustrates the summary of standards focusing on lithium-ion batteries.

Figure 2. overview of lithium-ion battery standards

- ISO/NP PAS 16898: Depending on vehicle dimensions and package constraints, the shape of battery packs and systems should follow a top-down procedure. The dimensional requirements on lithium-ion cells for automotive application are given by the battery system, which is influenced by the vehicle design. Therefore, ISO/NP PAS 16898, was developed to focus on electrically propelled road vehicles battery system design. This standard check for the requirements on dimensions for lithium-ion cells for vehicle propulsion.

- ISO 12405: ISO 12405 specifies test procedures for lithium-ion battery packs and systems, to be used in electrically propelled road vehicles. The specified test procedures enable the user of this part of ISO 12405 to determine the essential characteristics of performance, reliability, and abuse of lithium-ion battery packs and systems. The user is also supported to compare the test results achieved for different battery packs or systems. Therefore, ISO 12405 specifies test procedures for lithium-ion battery packs and systems, to be used in electrically propelled road vehicles. The specified test procedures enable the user of ISO 12405 to determine the essential characteristics of performance, reliability, and abuse of lithium-ion battery packs and systems. The user is also supported to compare the test results achieved for different battery packs or systems. Therefore, the objective of ISO 12405 is to specify standard test procedures for the basic characteristics of performance, reliability, and abuse of lithium-ion battery packs and systems. ISO 12405 consists of the following parts, under the general title Electrically propelled road vehicles — Test specification for lithium-ion traction battery packs and systems:

– Part 1: High power applications: This part of ISO 12405 specifies test procedures for lithium-ion battery packs and systems, to be used in electrically propelled road vehicles. The specified test procedures enable the user of this part of ISO 12405 to determine the essential characteristics of performance, reliability, and abuse of lithium-ion battery packs and systems. The user is also supported to compare the test results achieved for different battery packs or systems.

– Part 2: High energy applications: This part specifies the tests for high energy battery packs and systems.

– Part 3: Test specification for lithium-ion traction battery packs and systems (Safety performance requirements): This standard specifies test procedures for lithium-ion battery packs and systems, to be used in electrically propelled road vehicles. the specified test procedures enable the user of this standard to determine the essential characteristics of the safety performance of lithium-ion battery packs and systems - IEC62660: This standard is to specify performance testing for automobile traction lithium-ion cells and batteries – batteries that basically differ from the other batteries including those for portable and stationary applications specified by the other IEC standards. For automobile application, it is important to note the usage specificity; i.e. the designing diversity of automobile battery packs and systems, and specific requirements for cells and batteries corresponding to each of such designs. Based on these facts, the purpose of this standard is to provide a basic test methodology with general versatility, which serves a function in common primary testing of lithium-ion cells to be used in a variety of battery systems. It includes two parts: IEC62660-1 and IEC62660-2, and it is associated with ISO 12405-1-and ISO 12404-2.

– IEC62660-1: This part of IEC 62660 specifies performance and life testing of secondary lithium-ion cells used for propulsion of electric vehicles including battery electric vehicles (BEV) and hybrid electric vehicles (HEV)

– IEC62660-2: specifies the reliability and abuse testing for lithium-ion cells for electric vehicle application.

Agreement no. 769506

Agreement no. 769506